Well, i've never been very pleased with my side bender, it's a fox type but not as good as the real macoy or John Halls. And after breaking two sets of sides I knew it was time for a change......

I decided to make a Doolin style side bender as it looks fool proof to me (and I'm the perfect fool so I figured it would work great for me).

Now, I know that it's probably more complicated than is really needed for bending sides, but hey, there's always an other way of doing things right.

Mine is much closer to Mike's than Brad Way's was (post a couple of months ago) but both are based on the same spring princile. Thanks Mike for the cool design and Brad for posting yours, they both helped me build mine.

Anyway, since most everyone here want's to see pictures, I'll get on with it............

One of the additions which is very key in side bending IMHO is a way of telling how hot this all gets, so I got myself a good little digital thermometer with a long prob. It sure helped with the first bend.

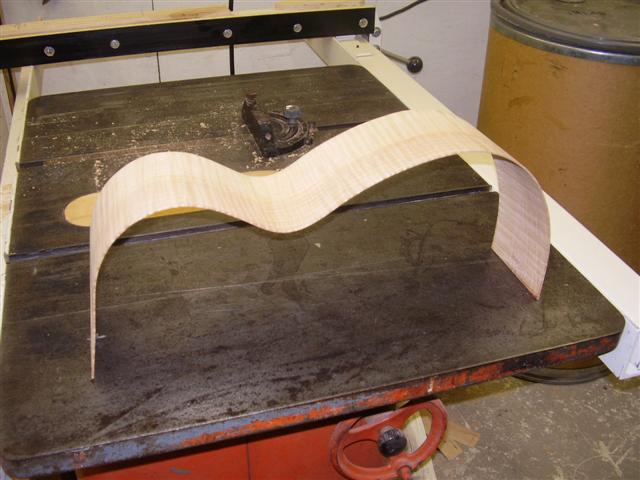

These are pictures of the first bend with it. A practice piece of curly maple. I figure this is a good test as it has lots of flame to worry about with the bend.

Here I am opening up the top slat, the wood didn't even move, it held it's shape perfectly.

Out of the bender unwrapped

And no scorching

I compensated the inside form for spring back, but there was none

so now I think I don't need to double cook it as I would like a little spring back or at least to figure out the correct shape.

so now I think I don't need to double cook it as I would like a little spring back or at least to figure out the correct shape.

Thanks for looking.