I have been building alot of clamps lately, trying to make whatever I can - mainly spool and gearing up to make some klemsia type cams.

I was perusing an issue of ShopNotes {I havent forgotten Serge

}

}

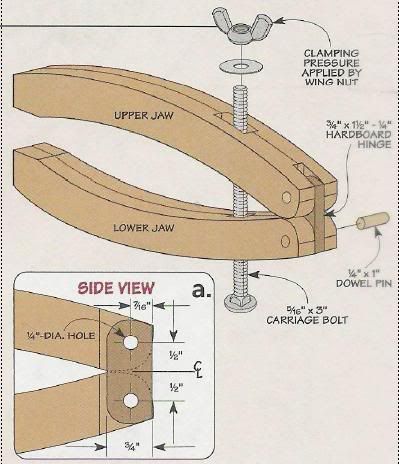

And I came across this shopbuilt clamp.

I was thinking this could be useful in guitar building, seeing as they are deep reach {or could be made so}.

Im sure there isnt as much pressure as a cam, but still these are good for something, mabye even I could add a cam to the end of these for extra clamping pressure?

opinion?

Cheers

Charliewood

looks promising!

looks promising!