After removing the bulk of material with spokeshave, rasp, coarse file,

and smooth file, on the straight section from nut to 10th fret or so, I use

wooden sanding blocks that are about 5" long x 2" wide that clamp the

paper at each end. Using them ensures an even and straight neck shaft. I

also have several that are 1" wide for narrower uses. For the curved areas,

such as the heal and transition area from shaft to headstock (again, after

filing), I use a piece of fairly stiff felt about 5/16" thick with sandpaper

wrapped around it. The felt has enough give to it to conform to overall

curves, yet it is stiff enough to ride across the smaller valleys and

inconsistencies and knock down the "peaks" until there are no more

valleys and peaks, only sweeping, smooth curves.

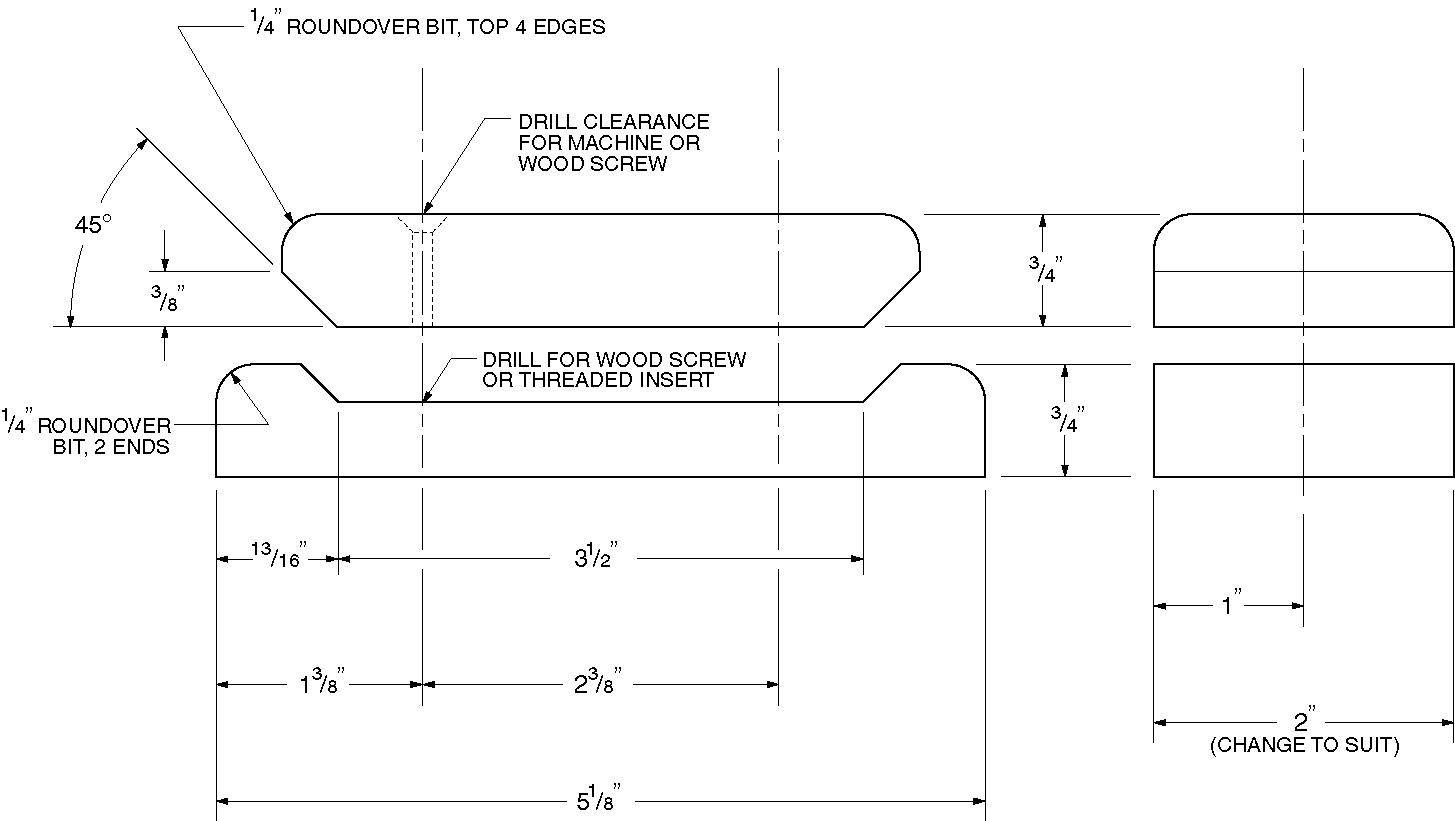

Here's a drawing of the block. It uses 2" wide strips cut off a standard

sheet of sandpaper.