I thought I post a tutorial on the way I fit a bridge patch as I'm sure it's differnt than most if not all. I like to do it after the X's are glued on vs. prior like most others.

I start with a very accurate layout just like other methods.

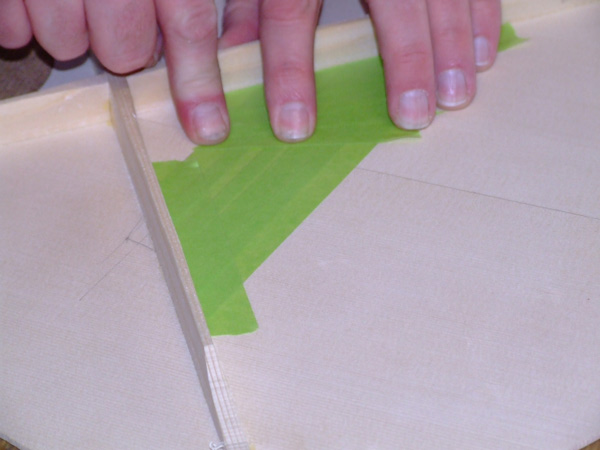

I the install the X's and tape up the area with one layer of masking tape like so and trim the tape to the X's

I then lay down a couple of other layers of tape in different direction to help hold the whole thing together.

I like a large radius on my bridge patches so I draw it on now using a beam compass.

I then care fully peel and trim the tape to the shape of the bridge patch.

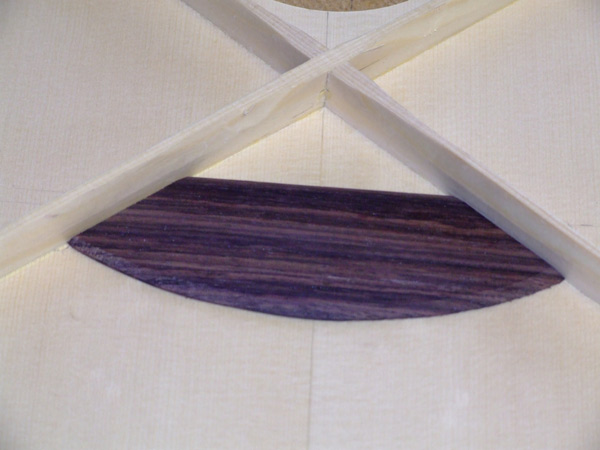

Tape the trimed pattern down to your material. I like cut off from rosewood backs myself.

Cut to size carefully and you have a nice fitting patch just in the right spot.

This all goes very quick, about the same amount of time it took me post this.

Maybe someone will find this of use.

Jim