Ok, ladies and gents… I haven’t been in the shop for a very long time. It sure felt good to get back to building a bit. I was about to bind my fingerboard when I got to thinking that I would be a great opportunity to make a little show and tell on how I go about sanding my miters.

When a piece is very small (height wise) I won’t hesitate of using just a chisel, but when the piece is higher as is the case of binding, I found nothing better or quicker than my trusty bench-top sander. This is a little method I developed as I went along and now I'm very happy with the results. It's not pretty but it works great for me.

First, I check to make sure the table is set perfectly square to the wheel.

Next is the fence.

Then I tape the two pieces to be mitered together. For the angle, I pretty much just eyeball it. As long as the two pieces get the same angle, you should be o.k.

A little something I found very useful. When I'm done, I take the two pieces, set them side by side and WITHOUT turning on the power to the sander (I reapeat, the sander is OFF) using the fence, I very gently clean up the sharp point. We're talking minimal pressure and about 1 inch of travel...

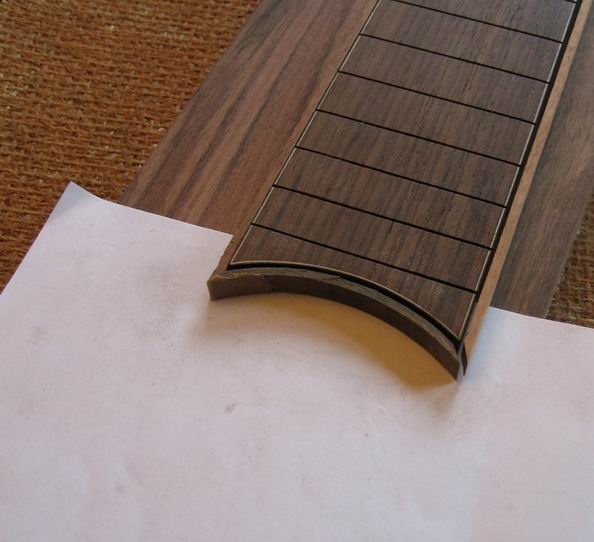

The result. Two very clean miters.

Now for me, the extention mimics the soundhole. I used my very high-tech bending apparatus pictured here: (note the technology dripping from that crepe block!)

Once the little piece is bent at the right angle, it's back to the bench-top sander to give it the right angles. For me, it's a lot of back and forth. I take off a bit off here and there until I'm satisfied with the fit. I know it sounds very obvious but make sure to have a piece significantly longer than you really need. The sander can take quite a bit off without you realizing it.

When I get eally close to the final fit, I'll swith to a hand file to take off last thou or so... or maybe not... it's up to you!

I want the dry-fit to be as perfect as I can get it.

I want the dry-fit to be as perfect as I can get it.

Voila! Just needs some glue...

Note that my FB was tapered and slotted already. I've also already glued on the purflings (before slotting). I did the purfling (which are full height) the exact same way for the exception that I used a little piece of backing wood to sand the angle in them since they are so soft and maleable.

Hope this can help some of you.

Oh yeah, this is where this FB should eventually wind up. Atop my 9 piece laminated neck (actually 13 if you count the 'extentions' with their lams - shown here just clamped on for a visual).

Cheers,

Al