Typically on old style "through saddle" bridges, if somebody wants a

pickup I will recommend top transducers or a good soundhole pickup like

the Baggs M1. This customer really liked the sound of his friends Baggs

Element though, and wanted one in is D-28V. These newer Martin

through saddles can be a real bear to remove, but since I had to do a

bridge reglue anyway I knew it would come out easy when I heated the

bridge.

I took a lot of pictures, so I'll try to be a concise as possible. Here is my

approach to an under the saddle tranducer for a through saddle.

First, Martin is no longer using a true through saddle. The slot is actually

closed on the ends, with the end of the cut filled with an ebony filler to

give the appearance of the square end of a true through saddle.

True through saddle pickups get feather thin at the ends and can be hard

to keep looking clean. I assume Martin chose this method as a way to

keep the saddle ends clean and consistant.

What I will do is cut a tiered saddle slot, with a recess to accept the

pickup while leaving the base of the saddle still fitting closely to the slot

bottom at the ends. First I will clean up the slot, removing very little

material. You need a fairly good slot routing jig for this whole job.

Next decide how deep the pickup recess has to be. The Element measures

out at about .035", and will compress down to around .033" with my

calipers.

Still having my saddle routing tool setup undisturbed from the last cut, I

will set the depth stop for .032" deeper than the initial clean up cut.

Here is the recess cut in. I routed it slightly longer than a standard

saddle.

Now to drill the access hole in the bottom of the slot, I always like to see

where the braces are. A couple of magnets and a ruler make this easy.

Coaxial, ribbon and film transducers don't like the 90 degree hole that

traditional piezo's use. I noticed when I got home that in my posing for

this shot I exagerated the angle, but you get the idea. Somewhere in the

range of 60-65 degrees above the slot should be sufficient.

Then I still like to go in with a micro chisel and soften the angle that it

will have to bend at as it leaves the slot.

Here's how it will fit.

Then the cussing begins as I try to remove the end pin to ream out the

hole. PLEASE DO NOT GLUE IN THE END PIN!

It is a taper fit pin and is designed to be removable.

NEVER GLUE IN THE END PIN! Thank you...

With the hole reamed I will make a quick note on how I like jacks

installed. Leave then not tight enough and they will come loose, and wires

will twist and break as the player tries to tighten it up by spinning the

end. Too tight and the finish will crack and lift - I've even seen end wedge

binding puckered out from the force. First get yourself an 18"-24" pice of

1/4" rod. I use my 18" 1/4" drill bit. This makes is simple and painless to

install and remove the jack as many times as necessary to get the

tightness right.

I like to set it so that when the nut is moderately tight it will bottom out

on the larger diameter of the jack. This way the washer doesn't flare

inward and crack the finish as I see so often. I can also then tighten the

nut more aggresively on the the jack to keep it from coming loose, still

without increasing the pressure against the body or finish. Start by

leaving the face of the large diameter of the jack set about 1/32" below

the surface of the finish. This will usually be pretty close, but keep pulling

it back out and adjusting the inner nut(s) until it feels right. I know I seem

picky about this, but improperly tightened jacks cause problems that I see

very often.

Finger tightened strap button ends that are chronically coming loose are

another common problem. The other side of that would be buttons

marred with plier marks, or even worse, Loctite or super glue. A simple

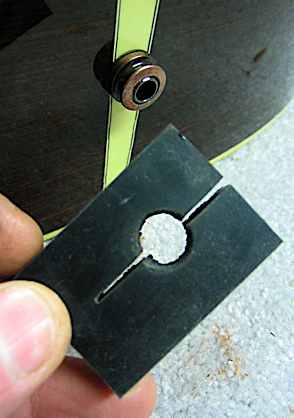

non-marking wrench is easy to make. For this tool I just drilled a hole

and cut a slot in a piece of 1/2" rubber.

Here it is in use - pretty fancy engineering, eh?

Okay, enough time on jack philosophy. On to the saddle. Always flatten

the bottom of your saddles on a surface block, float glass, or something

reasonably flat, especially after you have sanded the bottom on a belt

sander. When a saddle is sanded aggresively the surface will heat and cup

away from that side, leaving the center bowed out to be sanded more

than the edges. After the saddle cools, mark the base with a pencil and

sand it lightly on a block.

Here it is after a few strokes. It will look like this ever single time, whether

you are using bone, tusq, graphtech, etc.

After fitting the thickness and length it's time for me to refill the ends of

the slot. Normally this could be done after the saddle is shaped, but for

various reasons I needed the fills to be dried the following day and was

not going to have time to shape the saddle that day. I'll be using an epoxy

filled with ebony dust, although I'm sure there are black wood fillers that

would work just fine as well. First I wax the saddle to keep it from being

glued.

Mix some ebony dust with a small batch of my West System epoxy. It's

amazing how much this stuff absorbs. Whenever I add filler it seems I

have to add 2-3 times the volume of the glue in filler before it really

thickens.

Then fill the ends of the slot, custome molded to the saddle ends. I'm

doing this with the pickup out of the slot by the way. I want the saddle

fitting as tight to the sides and bottom to prevent epoxy from flowing in

to the slot.

Next day, trim the exess epoxy with a chisel and remove the saddle.

Then go about the usual business of making a saddle, file and sand the

saddle flush to the bridge at the ends, buff out the saddle and bridge.

After checking the pickup balance and having everything complete, I

decided to very lightly glue the ends of this saddle in. They are usually

glued in anyway, and this style of pickup leaves itself prone to moving if

the saddle were removed. This is not usually a problem on closed end

saddles, but just as a precaution I decided to rub some glue in the the

very ends to hold it in place.

Clean it up and here it is.

It's not something I do often, but this customer really wanted this

particular pickup in his guitar, and had been told by others that it was not

possible. I would have probably recommended against the extra expense

in most cases, but since I was already doing a bridge reglue, fret work

and a new bone saddle here some of the extra work would cross over. It

sounds just like it does in a standard bridge.