kencierp wrote:

Quote:

Unless you have a good understanding of the processes the different times and temperatures will not be of much use.

So the spruce that is tossed in an autoclave along with the planks at deck lumber processing facility -- is just as good as the material meticulously processes at the Taylor and Yamaha factories to their specs or by the Martin supplier to their specs?

Not sure what I said implies the two examples of processors you give produces the same material.

Quote:

The point is are we to just assume that all torrefied sound boards are made equal? And who has done the testing that indicates that to be true?

Why would they be the same, we have enough variability in non-treated tops and we do not expect them all to be equal. Can we test the untreated tops and have a simple measure of their worth?

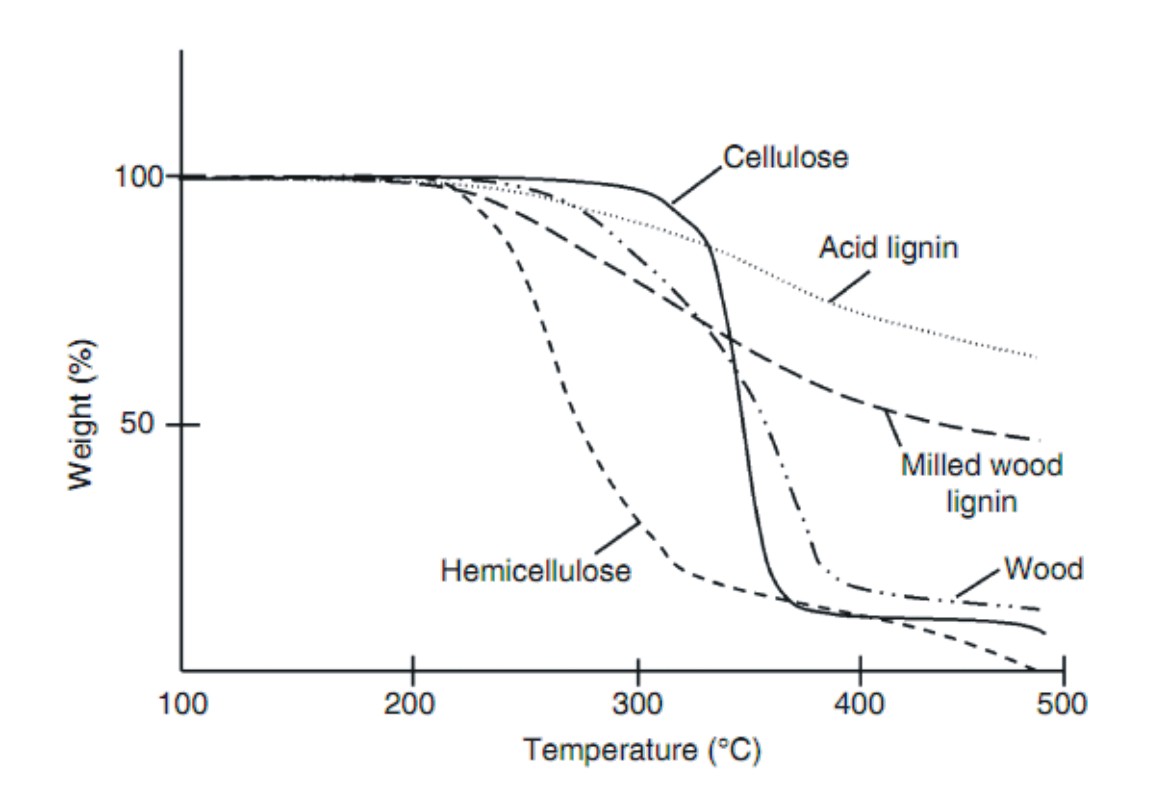

Wood is a complex material. The process changes this material. The time, temperature, amount of moisture present all change the reaction going on. One graph of torrefaction that I found.

The lower the temperature the less hemicellulose gets lost, the higher looses more. But then you start removing the other components. Given the time and temperatures that a guitar top processor uses will you be able to determine how much processing changed the wood? I would not be able to. Is there a graph comparing the processing at 375 F for two hours as compared to 385 F at one hour? The processors may have one, you and I, fat chance. At best we can compare their final product compared to other products.

I have worked in two industries where we take the raw material and cook them to change their properties. We had schedules that were found to work and followed them. That does not mean that a different schedule would not work and produce a similar result. We also sampled the material and modified the schedule if we found the raw material was different than the one originally used to set up the schedule. We also had different schedules to produce the product with a different 'flavor'.

As far as myself, I just look to see if I get the color change I want. Sort of like looking in the oven to determine if the pie is baked enough.