Quote: I have seen a lot of guitars with center seam failures...

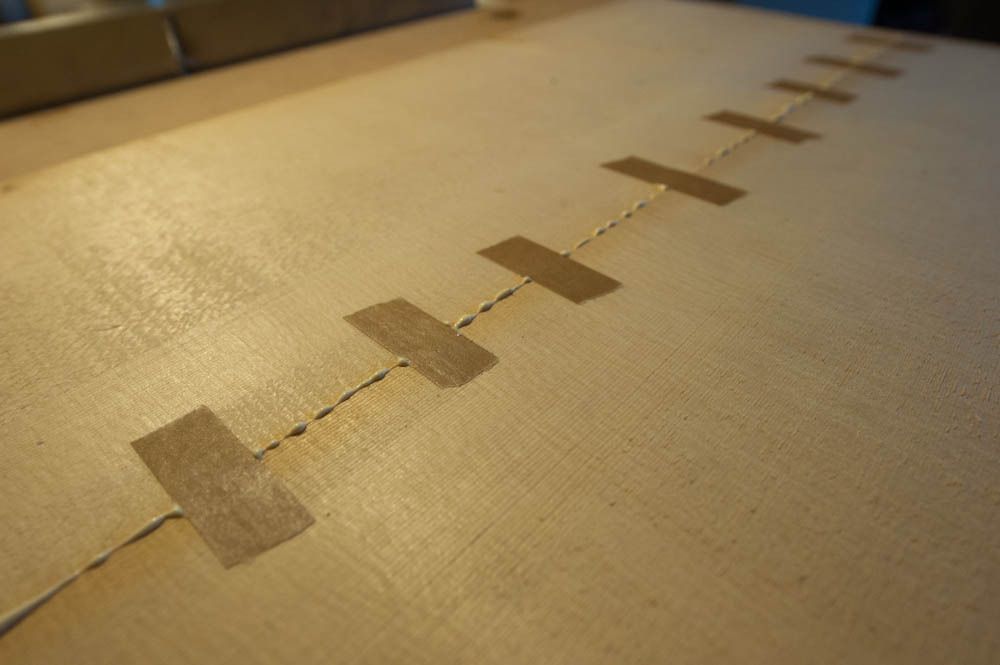

I try to get my joint as perfect as possible.... I want to stack the deck as much as possible in my favor as I can.

That said - I have seen the majority of those seam failures in the middle rather than on the ends - so it makes me wonder if their procedure allowed springing it in the center.

Thanks

I am not certain that cracks can easily open at the edges of the top, due to the increased gluing area of the linings and the tail block, or continue through the bridge area due to the bridge plate, so that leaves the center seam away from the edges as the likely failure point.

From what I've seen of this winter's crop of top cracks so far, the most common are from the back of the bridge plate to just shy of the binding and within an inch or so of the centerline. Thus far, only one centerline seam failure, and that is an old, repaired joint on a 70's era HD-28. On centerline glue failures, that we have in our repair records are on 1999-2005 Taylors, which is thought by the boss to be a combination of poor joinery and inadequate RH management in manufacturing. More recent Taylors don't seem to have nearly as many issues with center seams opening, so I have to assume they changed some procedures or had their jointer blades sharpened

|