Florian-

I used a Dremel to cut the binding channels on my first guitar - many years ago. It re-defined 'light cut' for me- you really have to take many very light cuts to get good results. It's also a bit tricky finding good bits for the job with the 1/8" shaft.

But it can be done. I don't think I'd pay the $$ for a commercial jig for a Dremel, though.

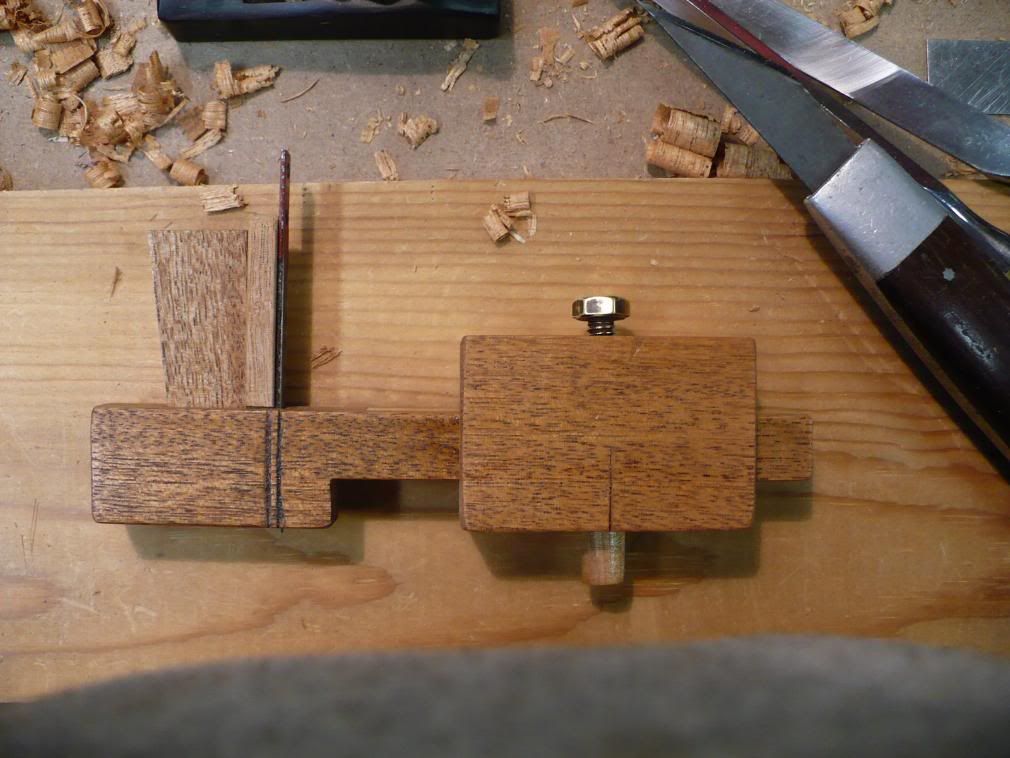

You can use a full-size router- again having a good bit is very important. One possibility is to use a router 'table' setup (you can make your own quite easily- just an open box that you clamp to the bench).

This was described in David Russell Young's book, which has some good 'low-tech' and economical ideas from the 'olden times'.

Attachment:

Young binding sm3.jpg

Attachment:

Young binding sm2.jpg

It does work- I built a few guitars with that setup for cutting binding ledges.

No matter what jig you use, you need to double check the ledge dimensions with a piece of scrap binding.

Cheers

John

![Uncle [uncle]](./images/smilies/surrenderflagqv6.gif)