Howdy David,

I just have a router mounted in a router table. Using a 1/4" carbide bit I set the depth and distance from the fence using a scrap piece of wood. For the fence, I used a 2 X 4 and ran it through the jointer to square it up making it level, plumb, square and straight, clamp it where you need it to be on the router table. I then make a pencil mark on the neck and one on the fence where I want to stop routing. Pretty simple really.

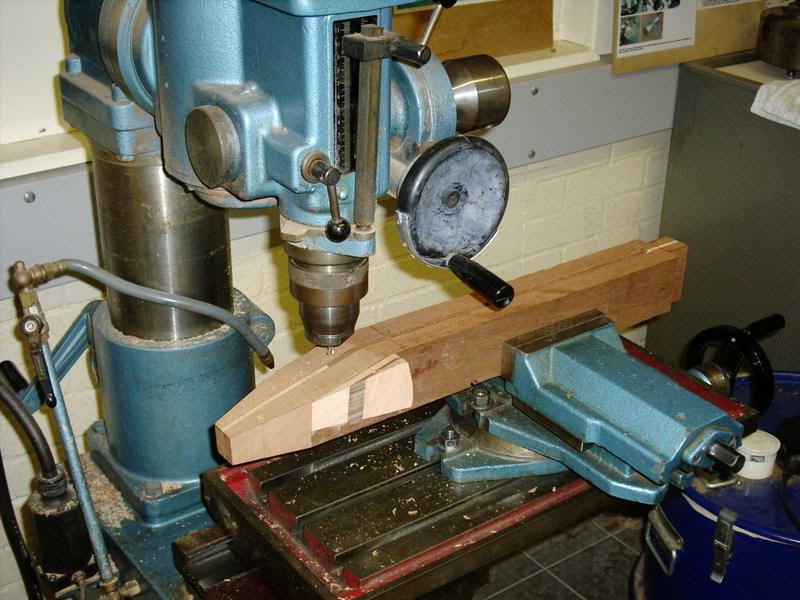

Here's a couple pictures: